Product description

The QT5-15 Fully-automatic Concrete hollow brick making machine is used for the production of all types and sizes of concrete blocks such as wall blocks, paving stones, road blocks, interlock blocks, you just need to change the mould to have all these products.

The electrical control system of the QT5-15 concrete brick making machine adopts PLC system, the computer interface operation, can realize random signal analysis, fault diagnosis and parameter setting, guaranteeing the best working effect of the machine.

Material storage device: using the closed belt conveyor, strict control of the small hopper discharge, so as to send with the use, to prevent the impact of the aftershocks of the concrete in advance of liquefaction, to ensure product quality and product quality.

Force fast and smooth fabric: fabric box stirring fork 360. Rotary motion, so that the fabric is uniform, fast, and smooth. To avoid the uneven phenomenon of wet material, product density is good, high quality. Free of material box impact, reduces noise, prolong its service life.

Unique and efficient vibration mode: the latest technology, adjust the speed of the motor to meet and guarantee the vibration of the host in the fabric of different vibration frequency and amplitude, thereby improving the quality of the products shorten the molding cycle.

Reasonable vibration distribution: the demolding cylinder will die locking strong vibration on the bedplate stiffness, reach Taiwan synchronous vibration, the amplitude distribution, achieved with a smaller deviation of mold intensity.

The body structure is novel, and strong: the body uses the high strength steel, the use of advanced welding technology welding manufacturing, and manufacturing quality, equipment, is durable, strong, stable, and reliable.

The concrete hollow block machine has a compact structure, stable performance, convenient operation and maintenance, small area, low investment, and high efficiency, suitable for large, medium, and small building materials enterprise investment.

Technical Parameters:

| Overall dimension | 4290×1950×2750mm | Vibration method | Synchronous mode of table & mould |

| Pallet size | 880×680×20mm(PVC) | Vibration frequency | 50-70Hz |

| Working area | 800×600mm | Machine Power | 45kW |

| Machine weight | 10500kg | Cycle time | 15s-25s depending on the product size |

Production Capacity:

| Specification of products (mm) | Number of blocks per pallet | Pieces/ hour | Pieces/8 hours | Pieces/300 days (two shifts) | ||

| Block | 400×200×200 390×190×190 |

6 | 1,400 | 11,520 | 6,912,000 | |

| Hollow Brick | 240×115×90 | 15 | 3,600 | 28,800 | 17,280,000 | |

| Paving Brick | 225×112.5×60 | 15 | 3,600 | 28,800 | 17,280,000 | |

| Standard Brick | 240×115×53 | 30 | 7,200 | 57,600 | 34,560,000 | |

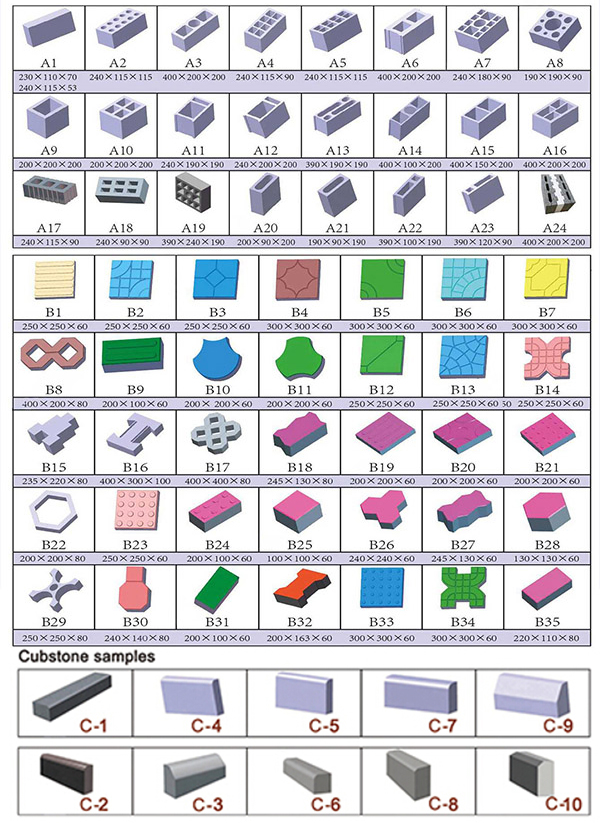

Block and Brick Models

Production Process

a. Wheel loader delivers raw material into the batching machine, need 1 worker

b. Cement silo delivers cement into the mixer through screw conveyor machine

c. Mixer mixes material, then deliver to block machine by conveyor belt machine, need 1 worker. If centralized control applied, no worker needed.

d. After producing blocks, block receiver delivers blocks to stacker

e. Forklift delivers blocks to curing area , need 1 worker

f. Curing area : Curing need 1~3 days, then take blocks out from pallet; need 1-2 workers.

g. After pallet empty, forklift delivers pallets to to pallet feeding machine

h. Sell blocks: Sell blocks and management; 1 worker

Total need about 5-6 workers in QT5-15 automatic interlocking block machine factory.

Note:

1. Complete line of QT5-15 block making machine need 2 or 3 pcs 40HQ containers.

2. QT6-15 Concrete block machine also need 1200pcs GMT fiber pallet or bamboo pallets when produce blocks.

3. Raw material proportion for your reference:

a. Concrete: 10% cement, 30% sand, 60% small stones

b. 10% cement, 90% stone powder

c. 10% cement, 30% fly ash, 60% stone powder