Product description

QT6-15 hydraulic concrete brick block moulding machine, it produces different kinds of blocks or bricks by changing molds. It is widely used to produce hollow blocks, solid blocks, color paving bricks, grass blocks, curbstones of various size and shape according to buyer local market.

It is controlled by PLC and form bricks with hydraulic pressure to guarantee finished blocks high density and strength.

Technical Parameter

| Dimension of host machine | 4350*2000*2700mm | Total power | 73kw |

| Weight of host machine | 7.5T | Vibration force | 70-90KN |

| Moulding cycle | 15-20s | Mixer model | JS500 |

| Water consumption | 5-8Ton/day | Pallet size | 900*700*25mm |

| Workshop area/Factory area | 250㎡/ 2500㎡ | Voltage | Adapt to local |

Production Capacit

| Specification | Pcs/Mould | Pcs/hour |

| Hollow block 400x200x200 (mm) | 6 | 1,200 |

| Hollow blocks 400x150x200 (mm) | 8 | 1,600 |

| Solid brick 240*115*53 (mm) | 40 | 8,000 |

| Paver 200x100x60 (mm) | 24 | 4,800 |

| Shape paver 200*163*60 (mm) | 16 | 3,200 |

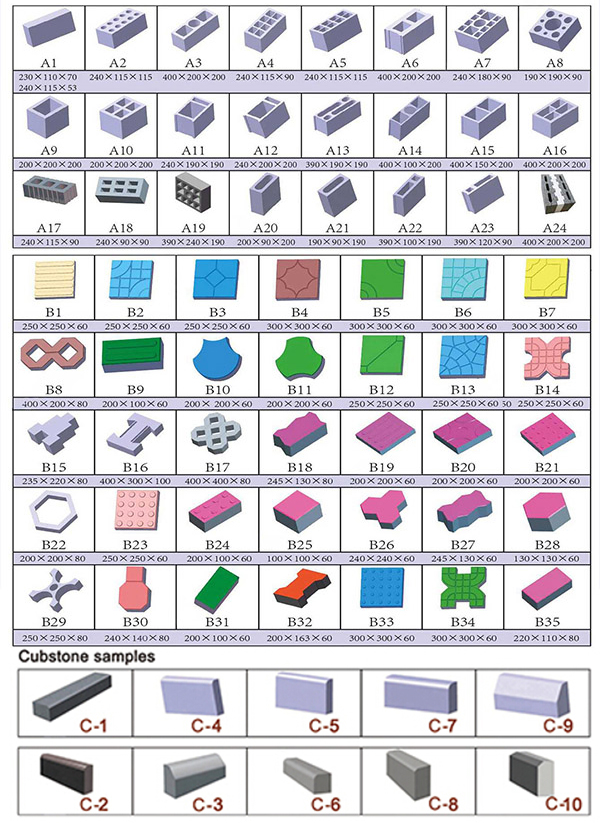

Block and Brick Models

Production Process

a. Wheel loader delivers raw material into the batching machine, need 1 worker

b. Cement silo delivers cement into the mixer through screw conveyor machine

c. Mixer mixes material, then deliver to block machine by conveyor belt machine, need 1 worker. If centralized control applied, no worker needed.

d. After producing blocks, block receiver delivers blocks to stacker

e. Forklift delivers blocks to curing area , need 1 worker

f. Curing area : Curing need 1~3 days, then take blocks out from pallet; need 1-2 workers.

g. After pallet empty, forklift delivers pallets to to pallet feeding machine

h. Sell blocks: Sell blocks and management; 1 worker

Total need about 5-6 workers in QT6-15 automatic interlocking block machine factory.

Note:

1. Complete line of QT6-15 block making machine need 2 or 3 pcs 40HQ containers.

2. QT6-15 Concrete block machine also need 1200pcs GMT fiber pallet or bamboo pallets when produce blocks.

3. Raw material proportion for your reference:

a. Concrete: 10% cement, 30% sand, 60% small stones

b. 10% cement, 90% stone powder

c. 10% cement, 30% fly ash, 60% stone powder