Product description

QT8-15 brick maker is a Automatic concrete block making equipment. By changing the moulds, it can produce diverse kinds of concrete wall blocks, such as: insulating block, hollow block, holes block, solid block; and paver blocks, such as: interlock block, Dutch block, curb; as well as concrete members, dry base brick, planter bricks, fence block for parks, air port and wharf, etc.

QT8-15 is one automatic hydraulic block machine, suitable for making hollow blocks, solid bricks, pavers and curbstone, this machine is automatic controlled by PLC, the cycle time is 15-25s, so production speed is very fast, for 8inches hollow blocks, it can produce more than 15000pcs per day. This machine adopts hydraulic pressure technology, the vibration and hydraulic pressure work together can ensure the block quality with a high density, and the block face looks very flat and very beautiful.

QT8-15 making machine running automatically, using hydraulic transmission, double cloth(basic material and color fabrics), vibration pressure, height and compactness of the function of control, the exciting force, simple operation, easy maintenance and reliable operation.

This equipment is the most advanced, reliable machine for making high quality, high intensity concrete blocks or fly-ash bricks. Multiple producing lines with different configurations can satisfy clients' manufacturing and capacity requirement of most concrete products.

Technical Specifications

|

Overall Dimension |

8000x1900x2900mm |

|

Rated pressure |

21Mpa |

|

Main vibration form |

Platform vibration |

|

Cycle Time |

15-25 seconds |

|

Vibrating Frequency |

2800-4500 rolls/minute |

|

Motors Power |

55.5 KW |

|

Pallet Size |

950x900mm |

|

Brick Raw Materials |

crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

|

Applied Products |

Hollow block, solid bricks, Paving blocks, Curbstone and so on |

|

Applied Fields |

widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

Features

It adopts material storage and distribution system to manage material storage and distribution so as to ensure accurate feed and precise dispensing for even density and high compactness of products.

It utilizes frequency conversion synchronous vibration mode and the vibration frequency can be adjusted according to different production requirements to attain low-frequency feeding and high-frequency molding. The change of amplitude and vibration frequency in the process of frequency conversion is beneficial for concrete compactness.

In a variety of data control systems for the production, it is easy and simple to operate and adjust the material changes to produce various products.

The automatic diagnosis system has alarming function, which can help timely troubleshooting. The remote data monitoring and recovery, system upgrading and fault diagnosis functions can be realized through network connection.

Production Capacity:

| pecification of products (mm) | Number of blocks per pallet | Pieces/ hour | Pieces/8 hours | Pieces/300 days (two shifts) | ||

| Block | 400×200×200 390×190×190 |

8 | 1,920 | 15,360 | 9,216,000 | |

| Hollow Brick | > | 240×115×90 | 18 | 4,320 | 34,560 | 20,736,000 |

| Paving Brick | > | 225×112.5×60 | 18 | 4,320 | 34,560 | 20,736,000 |

| Standard Brick | 240×115×53 | 36 | 8,640 | 69,120 | 41,472,000 | |

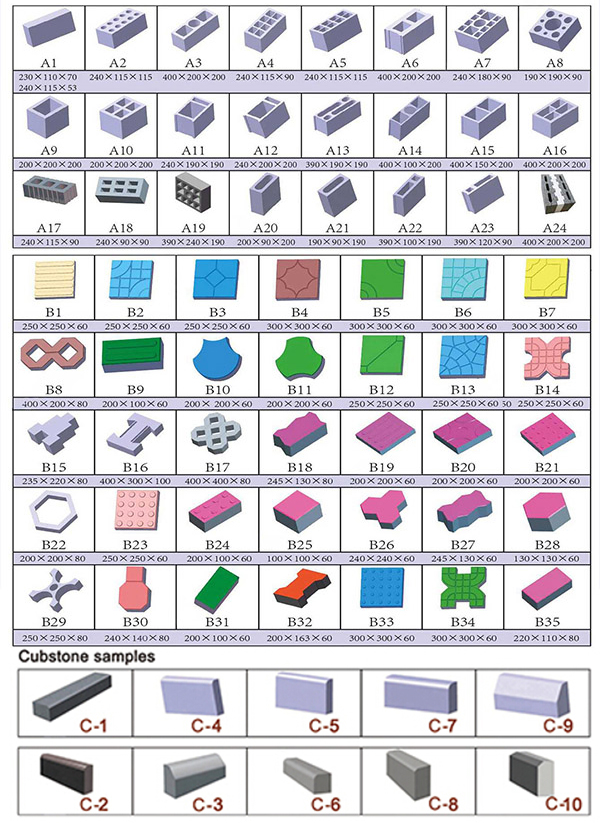

Block and Brick Models